paint film thickness test|how to check plating thickness : ODM Your clients rely on you to meet these requirements, so it's essential to test film thickness at every stage of the application process. This article explains the different testing methods, when you would use them and which paint . WEB30 de ago. de 2023 · Bet365 online é um site que oferece diversas modalidades de .

{plog:ftitle_list}

webCafe Casino is a Bovada sister site that was launched in 2016. Cafe Casino gets a huge reputation bump for being part of this trustworthy company. While its sister sites include poker and live games, Cafe is .

Wet Film Thickness (WFT) refers to the depth of a coating measured immediately after application, before drying or curing. Measuring WFT is important to predict the final Dry Film .

Dry film thickness (DFT) is the thickness of a coating or paint film after it has dried and cured on any type of substrate, whether ferrous, non-ferrous, or others.Your clients rely on you to meet these requirements, so it's essential to test film thickness at every stage of the application process. This article explains the different testing methods, when you would use them and which paint .A wide range of digital thickness gauges for accurate and reliable coating thickness measurement. A range of small and portable gauges from the simplest pull-off gauge for spot checks to the banana gauge. A range of destructive .10 important things coating thickness gauge users should know to ensure accurate DFT readings, including calibration, verification, surface roughness, environmental effects, and more.

Measure the coating thickness on your substrate with Elcometer dry film thickness (DFT) gages. One of the most accurate ways to measure paint thickness.The PosiTector 200 B1 (Standard model)* is the economical and most common solution for measuring the TOTAL coating system thickness. The PosiTector 200 B3 (Advanced model)* is capable of measuring both TOTAL coating thickness .

paint wet film thickness gauge

Coating thickness gauges measure paint thickness for quality assurance. Learn how they work and how to take accurate readings.Dry film thickness, coating thickness or paint thickness as it is often known, is probably the most critical measurement in the coatings industry. It provides vital information as to the expected life of the substrate, the product’s fitness for .This document describes methods for measuring the thickness of coatings applied to a substrate. Methods for determining wet-film thickness, dry-film thickness and the film thickness of uncured powder layers are described. For each method described, this document provides an overview of the field of application, existing standards and the precision.

A dry film thickness (DFT) gauge, often referred to as a coating thickness gauge, can be used to measure the thickness of any of these coatings when dry. Measuring dry film thickness is important when assessing cost, quality and service life of the coating. A coating which is too thick means that excessive material is being used, increasing costs.Paint Density: Measuring film thickness A number of factors affect coating thickness, including improper thinning, environmental conditions or mixing ratios when using two- or multiple-component coatings. These are all minor things that can add up to a major problem. by Susan Brimo-Cox. It may seem pretty elementary, but it’s not. Coatings .Get the Latest Standards on Dry Film Thickness of CoatingsThe 2012 edition of SSPC-PA 2, “Procedure for Determining Conformance to Dry Coating Thickness Requirements,” is available from the SSPC: The Society for Protective Coatings through sspc.org, under the “Standards” tab at the top of the home page.The 2012 edition of ASTM D7091 .Coating thickness, paint thickness, or dry film thickness (DFT) is an important variable that plays a role in product quality, process control, and cost control. Measurement of film thickness can be accomplished by selecting the best mil gage for the particular application. Why Dry Film Thickness Measurement is Important

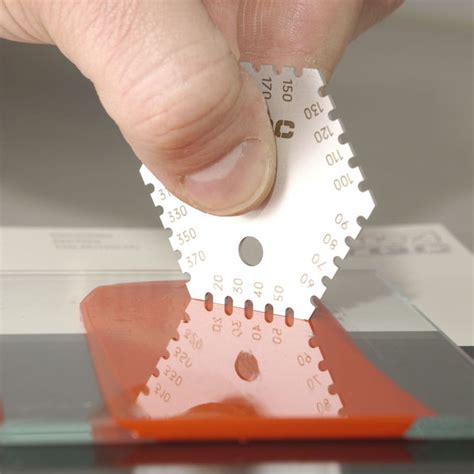

When the comb is removed from the paint, the teeth that were long enough to reach the paint will be coated at the end. Those that remain above the paint will have no coating on them. The thickness of the paint lies between the value of the shortest tooth to be coated and the adjacent tooth which will be the longest tooth to be uncoated.

Dry film thickness testing evaluates the thickness of a single layer or multiple layers of coating. The test provides information on the protective qualities of coatings by ensuring that coating thickness abides by ASTM standards and industry guidelines. Coating thickness directly affects a coating’s protective qualities, so thicker coaters .The PosiTector 200 C Ultrasonic Coating Thickness Gage (Standard or Advanced) is ideal for measuring most paint and coatings on concrete applications.With a paint thickness measurement range of 50 to 3,800 µm (2 to 150 mils), this thickness gage is recommended for customers desiring a single non-destructive measurement solution for most applications. 1.1 This test method describes the use of ultrasonic film thickness gages to measure accurately and nondestructively the dry film thickness of organic coatings applied over a substrate of dissimilar material. Measurements may be made on field structures, on commercially manufactured products, or on laboratory test specimens. These types of gages .The wet film thickness measurement is a quick and easy test. With the help of the technical information of the paint manufacturer, the dry film thickness can be predicted approximately with the following calculation: Dry film thickness=(Liquid paint film in µm x Solid content)/100. As a basis, paint systems can be classified as follows:

One of the most recognised, destructive methods in the coating industry is to use a paint inspection gauge (also referred to as a Tooke gauge or the PIG). The PIG is a popular method for determining dry film thicknesses on non-metallic substrates.. PIGs are available in various models. Some contain one cutter with an angled cutting edge suitable for a specific thickness . Conflicts can occur if a manufacturer and a customer of a finished good use different methods or types of instruments to determine coating thickness. This article will discuss the test methods available for determining coating thickness, common applications, and innovations in coating thickness instrumentation. Test Methods

10 important things coating thickness gauge users should know to ensure accurate DFT readings, including calibration, verification, surface roughness, environmental effects, and more. . Dry film thickness instruments that measure over steel operate on a magnetic principle. . a New York-based manufacturer of hand-held coating test .1. Scope 1.1 This test method covers the measurement of film thickness of dried films of paint, varnish, lacquer, and related products using micrometers. Procedures A and B utilize stationary micrometers and Procedures C and D, hand-held micrometers. Procedures A and C are not recommended for films less than 12.5 µm ( 0.5 mils) in thickness. Learn how to properly use a Wet Film Thickness Gauge for paint and coatings thickness testing. cohesive (failure within the coating film or the substrate). There are several methods that can be used to determine how well a coating is bonded to the substrate. This allows the coating to perform well. The primary methods .

Paint A has a volume solids of 50% and a wet film thickness measured at 250μm (10 mils) DFT = 250 x 50% = 125μm (5 mils) Paint B has a volume solids of 70% and the specification requires a dry film thickness of 100µm (4 mils) WFT=DFT/Volume solids=100/0.7= 143µm (5.7 mils)

For more information, visit: https://www.elcometer.com/en/coating-inspection/dry-film-thickness/dry-film-thickness-digital/elcometer-456-coating-thickness-ga.Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. Our measuring instruments solve a wide range of applications in coating thickness measurement. Whether single or multilayer coatings, painted or galvanized, magnetizable or conductive.

1.1 This test method covers the measurement of film thickness of dried films of paint, varnish, lacquer, and related products using micrometers. Procedures A and B utilize stationary micrometers and Procedures C and D, hand-held micrometers. Procedures A and C are not recommended for films less than 12.5 μm (0.5 mils) in thickness.thickness of a freshly applied coating material in powder form, measured immediately after application and before stoving 3.7 . highest value of the local film thickness found on the relevant surface area of a particular test specimen 3.12 mean film thickness1) .

cars that see powder coating are more uniform and have a higher film thickness. A car’s paint job is generally made up of 5 layers: Phosphate, E-coat, primer, basecoat, and clearcoat. Certain manufacturers apply the primer layer via powder coating, which can easily be twice as thick as your standard waterborne primer layer (60 µm compared to .

We think Tricomb Plastic Wet Film Gauges (W2008) are ideal for this, as you can quickly and cheaply test the wet film thickness and even leave them to dry as a way of recording the coating thickness. These wet film gauges are disposable and have metric values on the front side of the gauge, and imperial values on the back for your measurements.

By measuring the wet film thickness, it is possible to predict the dry film thickness. The dry film thickness can be calculated using the ‘solids to liquids’ ratio, also known as the volume solids content. For example: if the paint has a volume solids value of 80% and the wet film thickness is 200 µm, the dry film thickness will be 160 µm .Wet film thickness (WFT) combs and gauges are measurement tools used to determine the thickness of a coating immediately after it has been applied and before it has had time to dry or cure. These tools are incredibly crucial in industries such as painting, varnishing, enameling, and more, where the thickness of the coating directly affects its . the equivalent film thickness by reference to the graph. 3 MEASUREMENT OF DRY FILM THICKNESS BY MICROMETER METHOD 3.1 Scope Specifies a method for measuring the thickness of a dried paint film on a painted article or test panel to an accuracy of f5 pm. The measure-

paint thickness measuring instrument

WEBLOJA TUDO VAPE

paint film thickness test|how to check plating thickness